Naylor Lintels

The design of Naylor Prestressed Lintels complies with BS8110: part 1: 1997: Section 4. Naylor Lintels are manufactured in accordance with BSEN845 part 2: 2003.

Materials used in the manufacture of Naylor Prestressed Lintels comply with BSEN206 and BS8500. The prestressing wire complies with BS5896. Naylor Lintels have a low water absorption as a result of the dense concrete mix used in the manufacturing process. They can be used underground providing that the ends of the units are encased in a minimum of 45mm of mortar to the ends of the reinforcing strands.

All Naylor Lintels are wet cast and have a 2 c oncrete strength of 50 kN/mm . They are suitable to accept fixings providing that the tendons contained inside the unit remain undamaged.

All fire rated lintels produced by Naylor Lintels comply with BS8110:table 4.3:secton 2:1985.

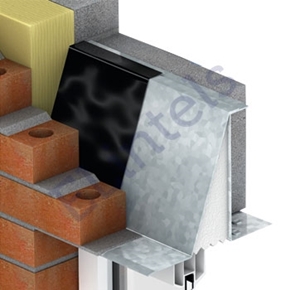

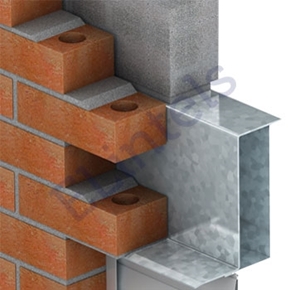

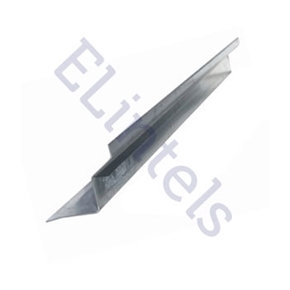

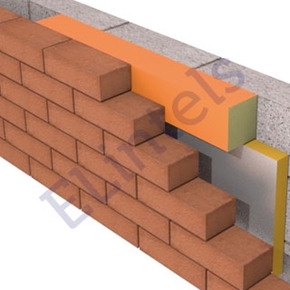

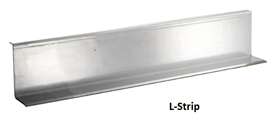

All L-Strip is manufactured from steel complying with BSEN10025 with a 2m inimum yield stress of 275n/mm . Zinc coating is galvanised to BS2989z2. Stainless Steel L-Strip is also produced, conforming to grade 304:S15:BS1449: Part 2.

Naylor Concrete Products Ltd operate to Certified ISO 9001 quality assurance standards.

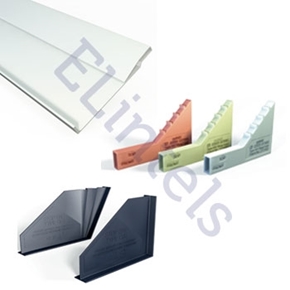

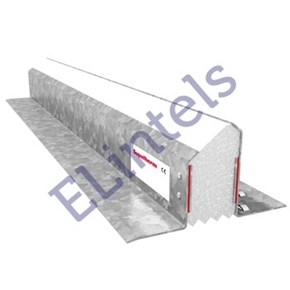

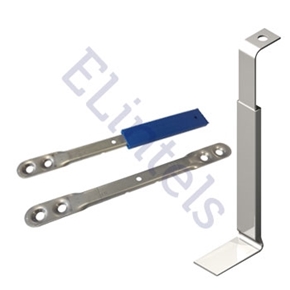

The Naylor Hi-Spec range of concrete lintels is one of the most specified and highly regarded lintel ranges in the UK. We keep all standard sizes in stock for delivery in 2-3 days.

Naylor padstones are manufactured using 50Kn/m2 strength concrete to ensure the perfect product for your needs with a HI-SPEC finish. All popular sizes kept in stock for speedy delivery.

Naylor Fair faced lintels, Fire spec lintels, Ultrafire and specials are all available from stock - email customerservice@elintels.co.uk for further details or telephone lintel sales on 01753 208755

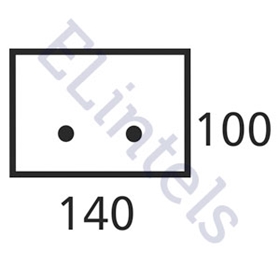

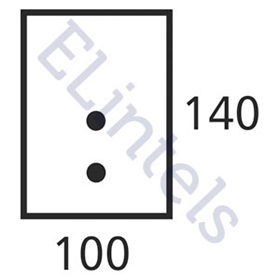

R3 140 x 100mm - High Spec Lintel

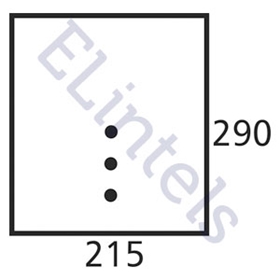

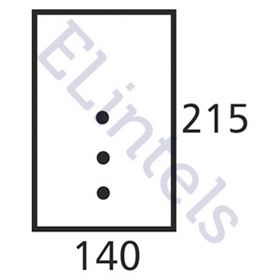

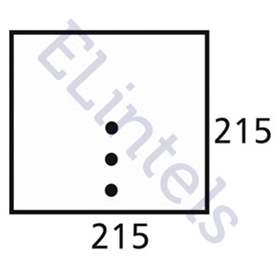

R8 140 x 215mm - High Spec Lintel

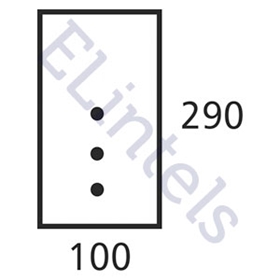

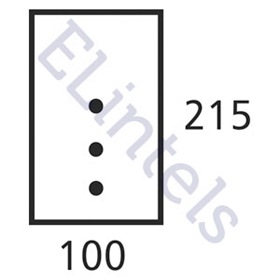

R9 100 x 215mm - High Spec Lintel

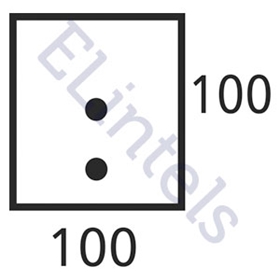

S4 100 x 100mm - High Spec Lintel

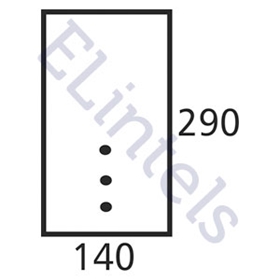

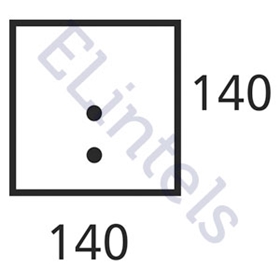

S5 140 x 140mm - High Spec Lintel

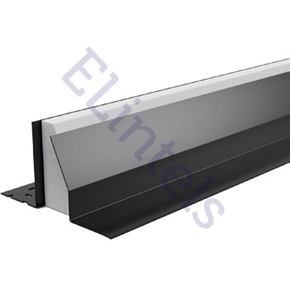

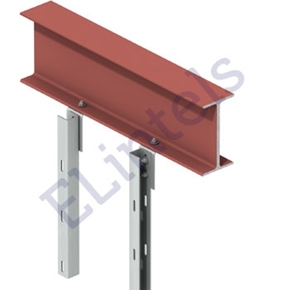

Naylor L-Strip Lintel LG215

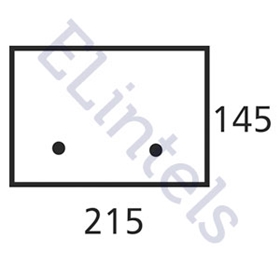

R6 100 x 145mm - High Spec Lintel

- 1

- 2